- Zhangjiagang pufa, Wholeheartedly provide you with high-quality service···

- (+86)0512-58633919

- pufajx@163.com

Product introduction

Centrifugal extractor is a new, fast and efficient liquid-liquid extraction and separation equipment. It is essentially different from traditional extraction equipment such as mixing clarifier and extraction tower in working principle. The centrifugal extractor uses the motor to drive the drum to rotate at high speed. The two liquids with different densities and immiscible with each other complete the mixing mass transfer under the shear force generated by the rotation of the drum or blade, and quickly separate under the centrifugal force generated by the high-speed rotation of the drum.

◆Mixing: custom precision mixing

◆Separation: high gravity forced separation

Work process

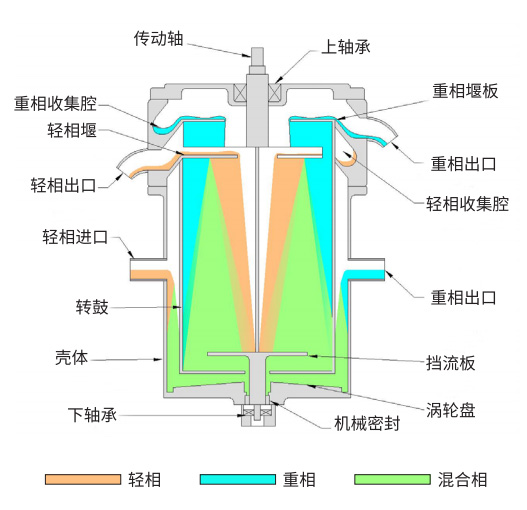

Mixed mass transfer process:

The light and heavy two-phase solutions enter the mixing area between the drum and the shell respectively from the two feed pipe orifices in a certain proportion to make the two phases mix and disperse rapidly, and the two-phase solution can obtain sufficient mass transfer to complete the mixing mass transfer process.

Two phase separation process:

The mixed liquid enters the drum under the action of the vortex disc or feeder. In the cavity area formed by the web, the mixed liquid quickly rotates synchronously with the drum. Under the action of centrifugal force, the heavy phase liquid gradually moves away from the center of the drum and towards the drum wall in the upward flow process; The light phase liquid with small specific gravity gradually moves away from the drum wall and towards the center. The clarified two-phase liquid finally enters the collection chamber through their respective weir plates and is led out of the machine by the lead pipe to complete the two-phase separation process.

Application field

Pharmaceutical and pesticide industries

Continuous extraction and separation of pharmaceutical / pesticide APIs and intermediates, extraction of traditional Chinese Medicine

Hydrometallurgy

Extraction of nickel, cobalt, copper, zinc, rubidium, cesium, manganese, lithium, boron and other elements and rare earth elements

Food & Fermentation Industry

Lactic acid fermentation broth extraction, citric acid fermentation broth extraction, natural plant pigment extraction (chlorophyll), etc

Fine chemical / petrochemical industry

Spices, cosmetics raw materials, extraction of organic solvents such as DMF and DMAC, and refining of lubricating oil

Chemical wastewater treatment

Phenol containing wastewater treatment, printing and dyeing wastewater treatment (H acid, t acid, etc.), DMF wastewater treatment, high concentration chemical organic wastewater treatment, naphthalene sulfonic acid wastewater treatment

Oil water separation

Water removal in oil and oil removal in water

Main features

Centrifugal extractor is a new, fast and efficient liquid-liquid extraction and separation equipment. It is essentially different from traditional extraction equipment such as mixing clarifier and extraction tower in working principle. The centrifugal extractor uses the motor to drive the drum to rotate at high speed. The two liquids with different densities and immiscible with each other complete the mixing mass transfer under the shear force generated by the rotation of the drum or blade, and quickly separate under the centrifugal force generated by the high-speed rotation of the drum.

Technical features of centrifugal extractor 1: new structure

1.The new top suspension structure is adopted —— the bearing and mechanical seal at the bottom are eliminated, and there is no risk of leakage

2.The mixing mechanism can be selected according to the material liquid system —— up to 6 mixing mechanisms can be set

3.Advanced multi cavity separation structure is adopted —— which can achieve better separation effect at low speed

4.Set a special quick replacement window for heavy phase weir plate —— when the weir plate needs to be replaced in different material and liquid systems, it can realize rapid replacement, which can avoid the problem of damaging the dynamic balance of the equipment when replacing the heavy phase weir plate by traditional equipment

5.The discharge mode of light and heavy two-phase feed liquid is optimized —— the equipment has the advantages of simple cleaning and not easy to be blocked

6.Modular production is adopted —— covering shell module, spindle module, drum module, bearing seat module, etc.

Technical characteristics of centrifugal extractor 2: Safety

1.The drum is made of polymer hybrid composite materials —— which can not only meet the strength required for equipment operation, but also solve the problem of corrosion of equipment by acid, alkali and solvent.

2.Static electricity conductive —— static electricity conductive devices are laid at the contact part between the shell and the material liquid, which can effectively prevent safety accidents caused by static electricity.

3.The feed liquid treatment area is isolated from the bearing —— the equipment is easy to maintain, and the high temperature ignition extractant caused by bearing damage can be avoided

4.It can realize data monitoring during equipment operation —— it can be equipped with on-line detection devices such as temperature, vibration, speed and current of bearings

Technical characteristics of centrifugal extractor 3: energy saving and environmental protection

1.The new centrifugal extractor is an upper suspension structure —— the bottom bearing and mechanical seal are eliminated; The bad production site environment caused by material leakage at the bottom is avoided.

2.The imported skeleton oil seal is adopted between the main shaft and the shell, with good sealing performance —— the equipment is completely sealed to ensure the friendly on-site environment.

3.The power consumption of the equipment is low, which can reduce energy consumption —— the motor power of the new cwl650-m centrifugal extractor is 4 / 5.5kW, the power consumption of the traditional annular 650 centrifugal extractor is 37KW, and the new equipment is about 1 / 10 of that of the traditional model.advantages of simple cleaning and not easy to be blocked

4.Modular production is adopted —— covering shell module, spindle module, drum module, bearing seat module, etc.

Technical features of centrifugal extractor 4: high degree of automation

1.The new centrifugal extraction uses centrifugal force to separate two-phase materials without manual adjustment.

2.The equipment can be produced continuously, the operation is simple, and the labor input cost is reduced.

Centrifugal extractor Technical parameter

| Models | Basket Dia(mm) | Maximum flux(L/h) | Tube diameter(mm) | Power(kw) | Weight(kg) | Dimension(L*W*H)(mm) |

| CTL25-F | 25 | 10 | φ10 | 0.09 | 5.5 | 230×230×800 |

| CTL50-F | 50 | 50 | DN20 | 0.18 | 32 | 400×370×900 |

| CTL150-F | 150 | 1000 | DN40 | 1.5 | 220 | 620×630×1250 |

| CTL250-F | 250 | 3000 | DN50 | 1.5 | 320 | 750×750×1400 |

| CTL350-F | 350 | 8000 | DN65 | 2.2/3.0 | 520 | 950×950×1600 |

| CTL450-F | 450 | 15000 | DN80 | 4.0 | 860 | 1070×1070×1800 |

| CTL550-F | 550 | 30000 | DN100 | 4.0 | 1320 | 1200×1200×1760 |

| CTL650-F | 650 | 60000 | DN125 | 4.0/5.5 | 2000 | 1380×1380×2250 |

| CTL900-F | 900 | 15000 | DN150 | 7.5 | 2500 | 1690×1690×2480 |