- Zhangjiagang pufa, Wholeheartedly provide you with high-quality service···

- (+86)0512-58633919

- pufajx@163.com

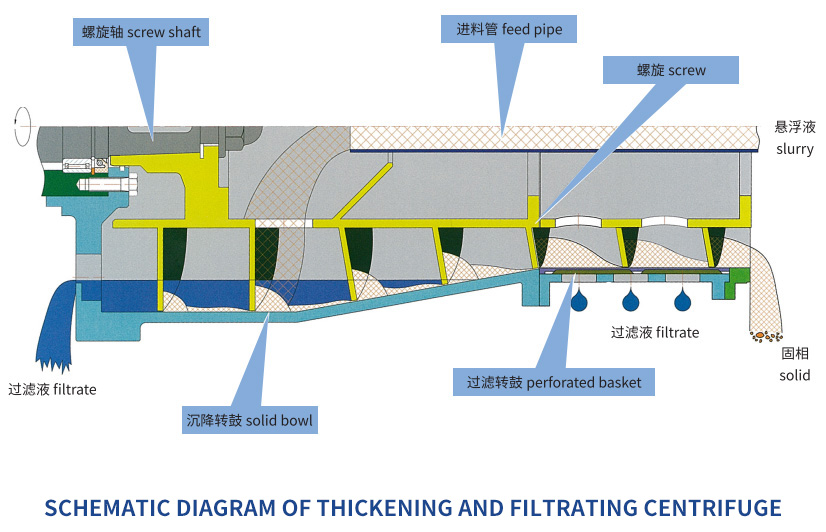

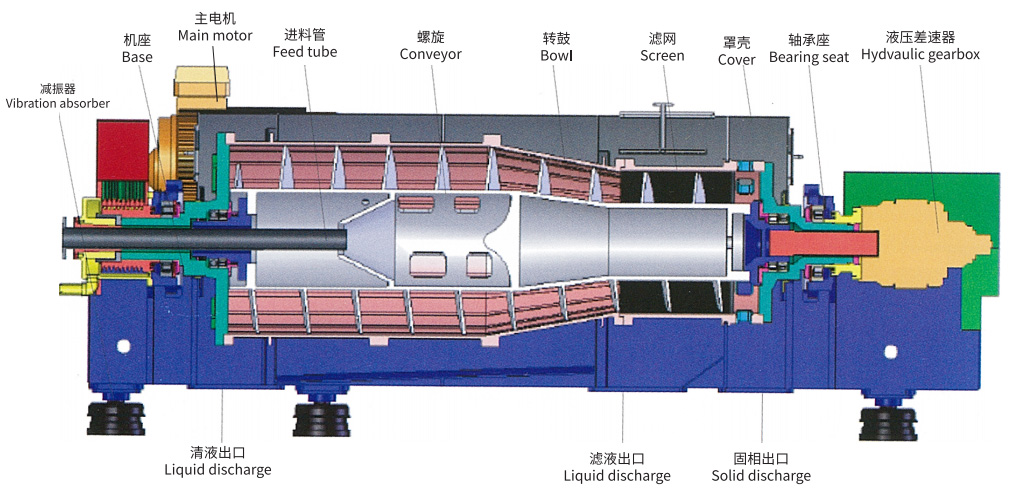

Operating principle

This centrifuge is designed on the technology of screen filter and scroll discharge, with additional pre- thickening device, fficient separation can be realized for slurry with low solid concentrate, and efficient recycling for slurry with fine particles. Slurry is introduced into the centrifuge pre-thickening section for solid liquid separation through distribution port in the middle of screw parts by a feed pipe. Most of the clarified liquid after sedimentation will be drained out through the adjustable overflow device in the rear part of centrifuge bowl, while the solid phase after thickening will be conveyed to the centrifuge filter screen for final dewatering If necessary, solid phase can be washed.

According to process requirement, clarified liquid and filtration liquid can be drained out separately, or can be drained out together though a slingle or double hydrocyclone. Loss of the fine particles is relatively low, if separated liquid can be returned to the feeding tank, minimum loss of fine particles can be realized. Solid phase on the cylindrical basket after filtration will be conveyed from end the filter screen to the solid outlet tank by screw in axial direction.

The screen decanter is a combination of a solid bowl decanter centrifuge and a screen worm centrifuge with exceptional dewatering results.

In the decanter component, the feed suspension is first pre-thickened, i.e it is extensively dewatered in the conical part of the solid bowl. The liquid is clarified in the cylindrical part and fnallyl discharged. The pre -thickened solids are transported into the cylind rical screen section by the worm where additional dewatering is achieved.

The screen decanter centifuge is particularly applicable for the solid-liquid separation in the mining, mineral, refining, salt production and other industries. It features large processing capacity and low moisture rate of solid content.

Applications

Application range:

1.Slurry of crystals, particles or fibers with good sedimentation performance

2.In the particle size distribution, particle size d≥0.08mm

3.Solid concentration in feeding is 5 ~ 60%Wt

4.Slurry with small amount of organic matter or tar in viscous material

Successfully used for:

1.Ammonia sulfate wastewater and process product separation

2.Ammonium chloride wastewater and process product separation

3.Potassium sulfate separation

4.Potassium chloride separation

5.Ntrocotton separation

6.Biodegradable plastic separation

7.CPE insulating material separation

Main features

1.It is designed on the technology of screen filter and scroll discharge, with additional pre - thickening device to improve the separation eficiency, can be used for slurry with low solid concentrate, filtration after thickening, efficient recycling for slurry with fine particle;

2.Bar-type filter screen design making basket with long working life;

3.Whole-type screen and chip-type screen are optional according to different material and user requirement: whole-type screen is convenient to dismount, no need to remove the scroll;

4.while chip-type screen with low maintenance cost, no need to integral replacement

5.Unique feeding structure design, preventing the material recoil and influence separation effect;

6.Sedimentation separation making mother liquid with high clarity, low solid content;

7.0° angle perforated basket, with higher dehydrate efficiency;

8.Mother liquid in filter section with very tew fine particles, can be recycles separately.

9.Large capacity, and product with low humidity.

LWZ Technical parameter

| Items | Models | ||

| LWZ 530*2120 | LWZ 650*1950 | LWZ 1000*3000 | |

| Basket Dia(mm) | 530 | 650 | 1000 |

| L/D Ratio | 4 | 3 | 3 |

| Bowl speed(r/min) | 2800 | 2500 | 1500 |

| Max separating factor(N) | 2327 | 2272 | 1258 |

| Main motor power(KW) | 55 | 90 | 132 |

| Weight(kg) | 5000 | 7500 | 16000 |

| Dimension(LxWxH)(mm) | 4870*1230*1520 | 4730*1720*1560 | 5220*2610*2000 |