- Zhangjiagang pufa, Wholeheartedly provide you with high-quality service···

- (+86)0512-58633919

- pufajx@163.com

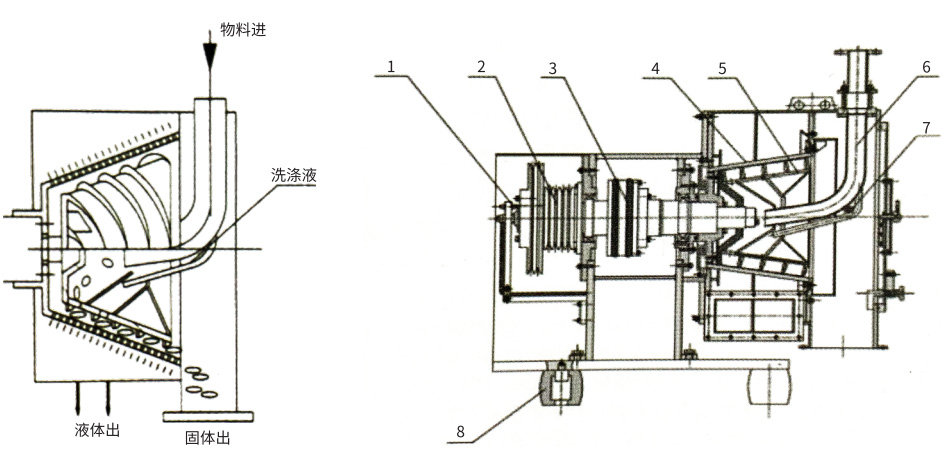

Operating principle

Operations such as feeding,dehydrating,washing and discharging etc. Can all be processed continuously,by LWG centrifuge on its full speed. Host machine starts with power on and speeds up automatically. Open the feeding valve when predetermined condition is met. Products to be separated enters into centrifuge along pipeline and is distributed onto drum wall through feeding holes on the smaller end of spiral wheel. Under the effect of centrifugal force, liquid phase in suspension will be thrown out through screen and holes on drum wall and discharged from centrifuge,while solid phase remains in the screen to form a thin filter residue. In the centrifugal forcefield,filter residue is gradually pushed from small end of the drum to big end by two forces: one component of forces points to the big end paralleled with the drum generatrix, the other is the thrust force toward the big end by spiral bar's motion. Filter residue is turned constantly by spiral bar to enhance separating effect. Filter residue pushed out of the big end is finally discharged from residue outlet, thus solid-liquid separation is finished.

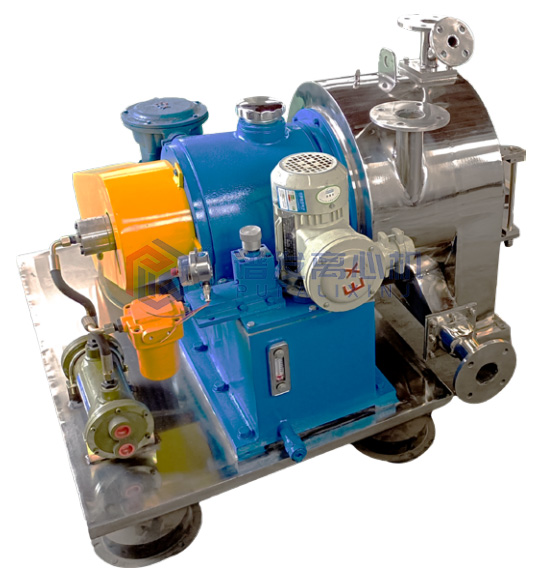

LWG Screen Filtration Centrifuge is a horizontal with the function of Continuous working, continuous spiral discharging. It is mainly used for separating and dehydrating suspension with solid-phase grains ranging from 0.05 to 10mm, It is applied in chemical, foodstuff chemical fiber, mining and metal melting, pharmacy and light industy.

Main Characteristics:

1.Continuous operation,spiral discharging and large capacity.

2.High dehydration rate of solid phase,good washing effect and high efficency.

3.Tight structure and convenient operation and maintenance.

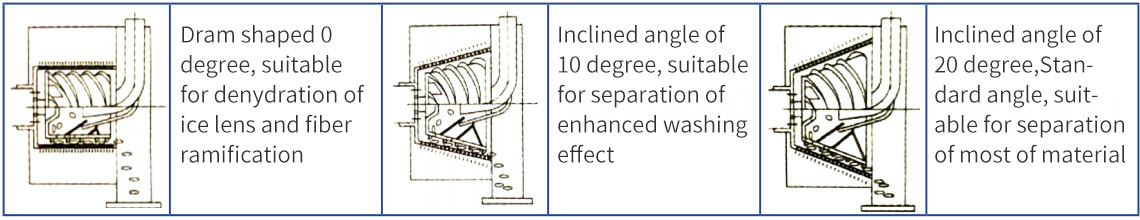

LWG spiRal pArts can be SpEciAlly designed

LWG Screen Filtration Centrifuge can be bucket or cone shaped. Discharging speed and the time of filter cake staying on screen mesh are predetermined spiral can be of different angles for determining different discharging speed and time of filter cake sraying on sceeen mesh, which is in accordance with customer's process requirements.

1/Security facillity

2/Beltwheel

3/Differential gear

4/Revolving drum

5/spiral

6/Feeding pipe

7/Washing pipe

8/Shock absorber

LWG Technical parameters

| Items | Models | |||||

| LWG-250*190 | LWG-350*300 | LWG-450*320 | LWG-530*380 | LWG-630*465 | LWG-800*500 | |

| Basket Dia(mm) | 250 | 350 | 450 | 530 | 630 | 800 |

| Basket Lenght(mm) | 190 | 300 | 320 | 380 | 465 | 500 |

| Max speed(r/min) | 3500 | 3000 | 2600 | 2000 | 1850 | 1500 |

| Max separating factor(N) | 1800 | 1762 | 1702 | 1185 | 1205 | 1008 |

| Speed difference beween drum and spiral | 18 | 24 | 22 | 23 | 24 | 24 |

| Main motor power(KW) | 5.5 | 15 | 22 | 30 | 37/45 | 75 |

| Dimension(LxWxH)(mm) | 1150*1100*800 | 1550*1450*1257 | 1550*1382*1323 | 1730*1920*1475 | 2120*2190*1660 | 2700*2100*1700 |

| Weight(kg) | 700 | 1800 | 2250 | 3200 | 3800 | 6000 |

| Processing capaliliy(³m/h) | 0.5-1.5 | 3-15 | 3-18 | 6-20 | 8-30 | 15-45 |