- Zhangjiagang pufa, Wholeheartedly provide you with high-quality service···

- (+86)0512-58633919

- pufajx@163.com

Operating principle

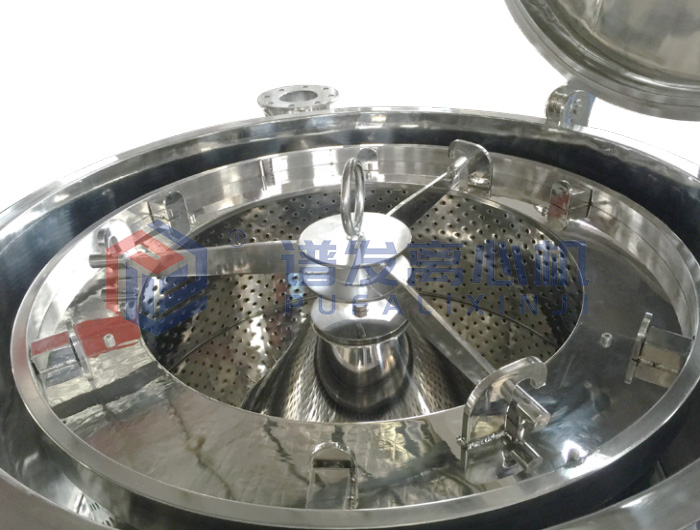

Once the materials to be separated enter the fast - spinning basket, it will be filtrated by the filter liner under the centrifugal force. The liquid flows out through the liquid outlet, but solids deposit on the internal wall of the basket.Once the solid cake reaches the rate capacity, feeding stops. Wash the solids cake, and then drain out the washing water. Finally stop the machine. Use the lifting tool or crane to lift out the filter cloth with solid cake, and move to the discharging place. Open the filter cloth and discharge the solid cake. Put the filter cloth back to the centrifuge and move to next batch.

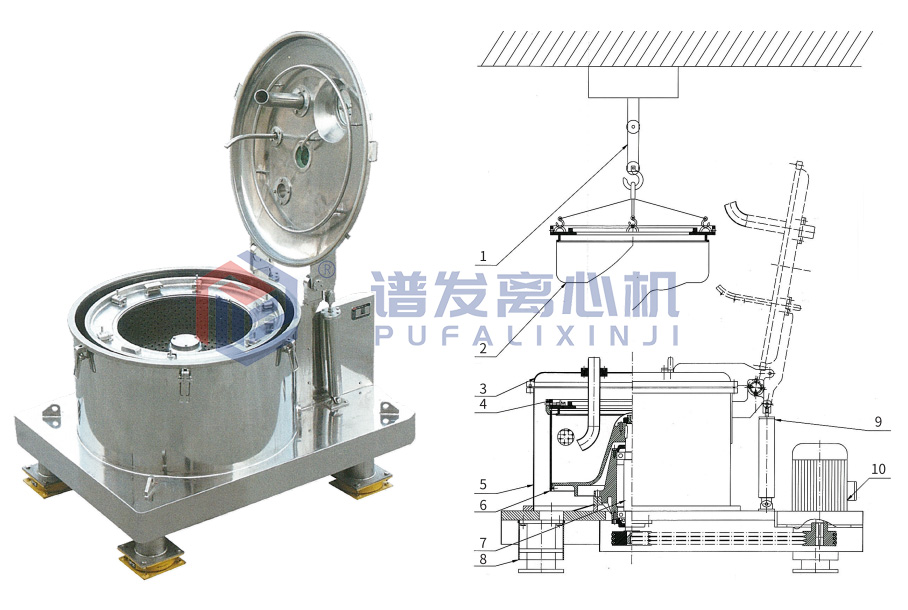

1/The lfting device

2/The lifting

3/The top coverbr

4/The hanger

5/The shell

6/The drum

7/Drive mechanism

8/The shock absorber

9/Open institutions

10/The motor

Main applications

Apply to separating material with granulate particle shape, but also fibers, like plasters, bluestone, potassium chloride, borax, dyestuffs, pesticides, salts, gourmet powders, foodstuff additives, chemical flavors, antibiotics, vitamins, the metals like copper, zinc and aluminum, metal products, sludge, etc.

Main features

1.Inverter start-up, smooth starting, adjustable relative centrifugal force.

2.Discharge cake by lifting out filter cloth is highly efficient with low labour intensity; No damage to the particles; Wide range of applications.

3.Well- designed structure and polished surface leaves no residual heel. With big hinged cover, it is easy to clean the gap between the case and the basket.

4.Overall weldling structure between the base and the case ensures high carrying strength.

5.Platform base design lowers the center of gravity and requires minimum installation space. The platform base can be used for operation platform.

6.Liquid-damping vibration isolators, simplifty the routine maintenance.

7.Big hlinged cover, feed pipe, wash pipe, observation glass and light.

8.Automatic CIP system (optional) cleans the internal surface of the case, the basket and liquid slot to meet the clean requirement in accordance with GMP standards.

9.Tightness structure with silicone rubber or fluoroelastomers seals. Nitrogen protection system (optional) is for anti-explosion applied to poisonous, flammable and explosive environment.

10.Equipped with hydraulic suspension arms (optional), which is easy for discharging and complies with the sanitation requirements.

PSD Technical parameters

| Items | Models | |||||

| PSD 800 | PSD 1000 | PSD 1250 | PSD 1500 | PSD 1600 | PSD 1800 | |

| Basket Dia(mm) | 800 | 1000 | 1250 | 1500 | 1600 | 1800 |

| Basket Volume(L) | 120 | 200 | 400 | 600 | 800 | 910 |

| Max. load(kg) | 150 | 250 | 500 | 800 | 1000 | 1100 |

| Max.Rotating speed(r/min) | 1200 | 1000 | 1000 | 850 | 850 | 780 |

| Centrifuge force | 645 | 680 | 700 | 607 | 647 | 612 |

| Motor(kw) | 5.5 | 7.5 | 18.5 | 30 | 37 | 37 |

| Dimension(LxWxH)(mm) | 1600*1200*1320 | 1800*1400*1500 | 2300*1800*1780 | 2800*2200*1800 | 3000*2200*2150 | 3300*2600*2150 |

| Weight(kg) | 1500 | 2000 | 3000 | 6000 | 9000 | 10000 |